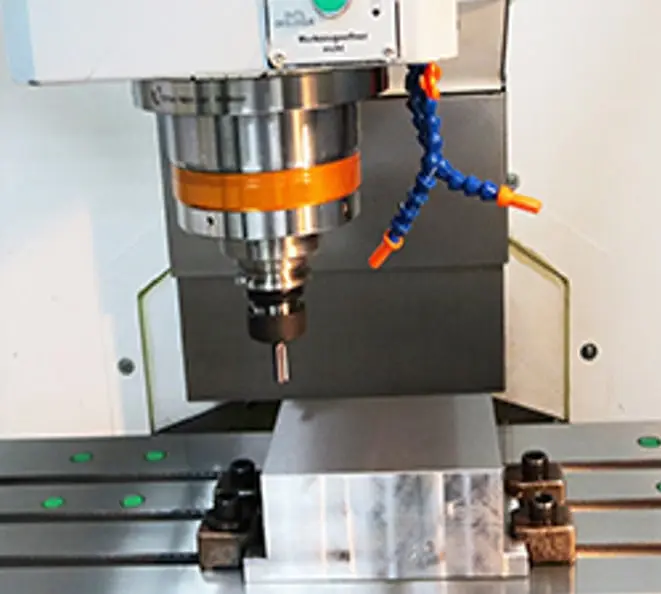

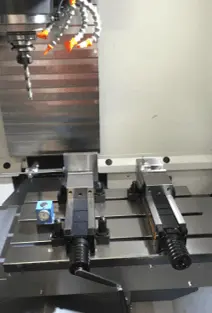

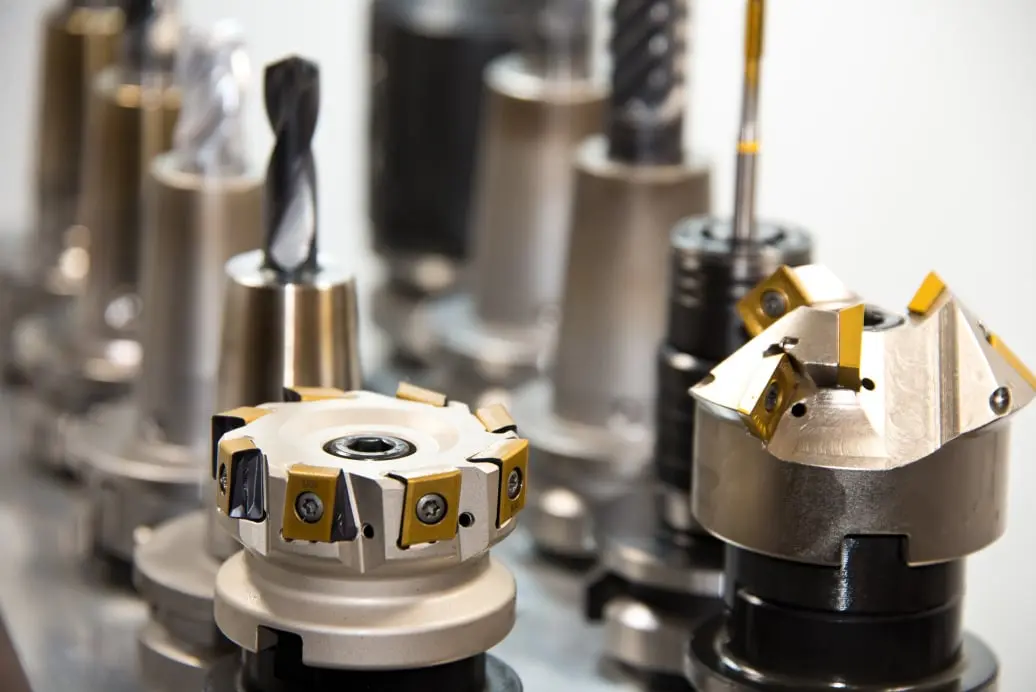

CNC machining center

We have a department of our own CNC machining center primarily intended for the production of parts and components for the construction of machines and equipment developed and produced by us, servicing of our customers' machines and equipment, including ensuring the production and supply of spare parts.

As standard, we offer our customers and also ensure the production and delivery of medium and small series according to the drawing documentation made or supplied by us.

Preparation of machining operations is carried out in SW CamWorks, including the necessary simulations.

On modern machines, we are able to process a wide range of materials, from hard metal, stainless steels to plastics and composites.

For parts, we provide:

surface treatment by anodizing, galvanizing, blackening, nickel plating, sandblasting.

Wet and powder coating.

Refinement by cementation, hardening, nitriding.

The result of our work is quality products with high repeatable accuracy for use in industry.