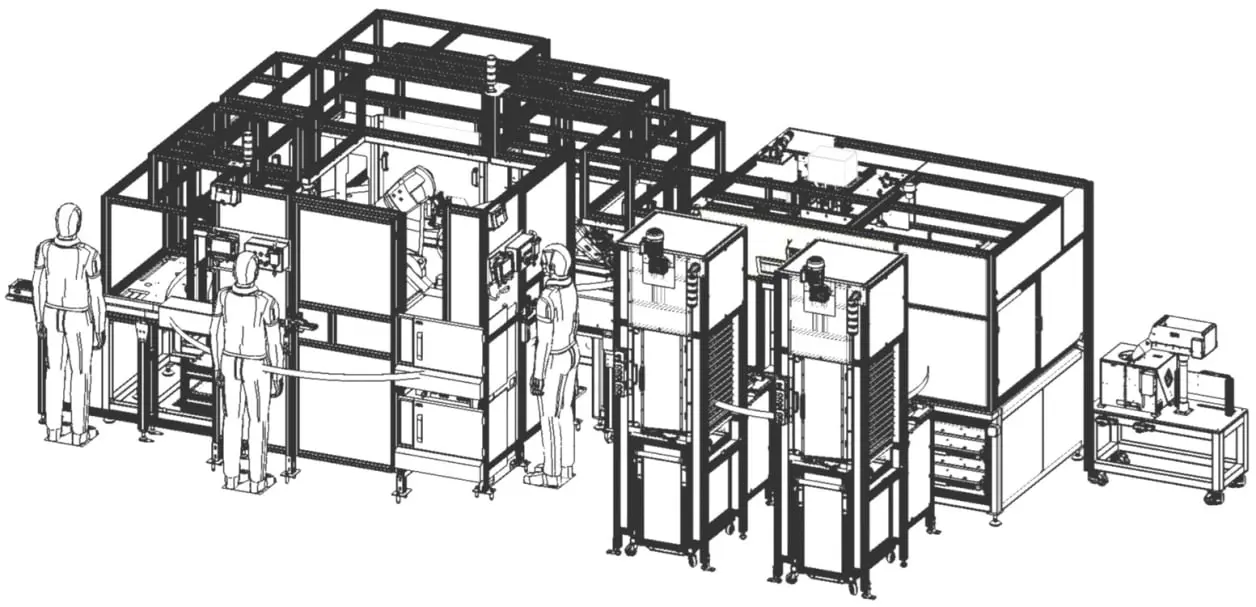

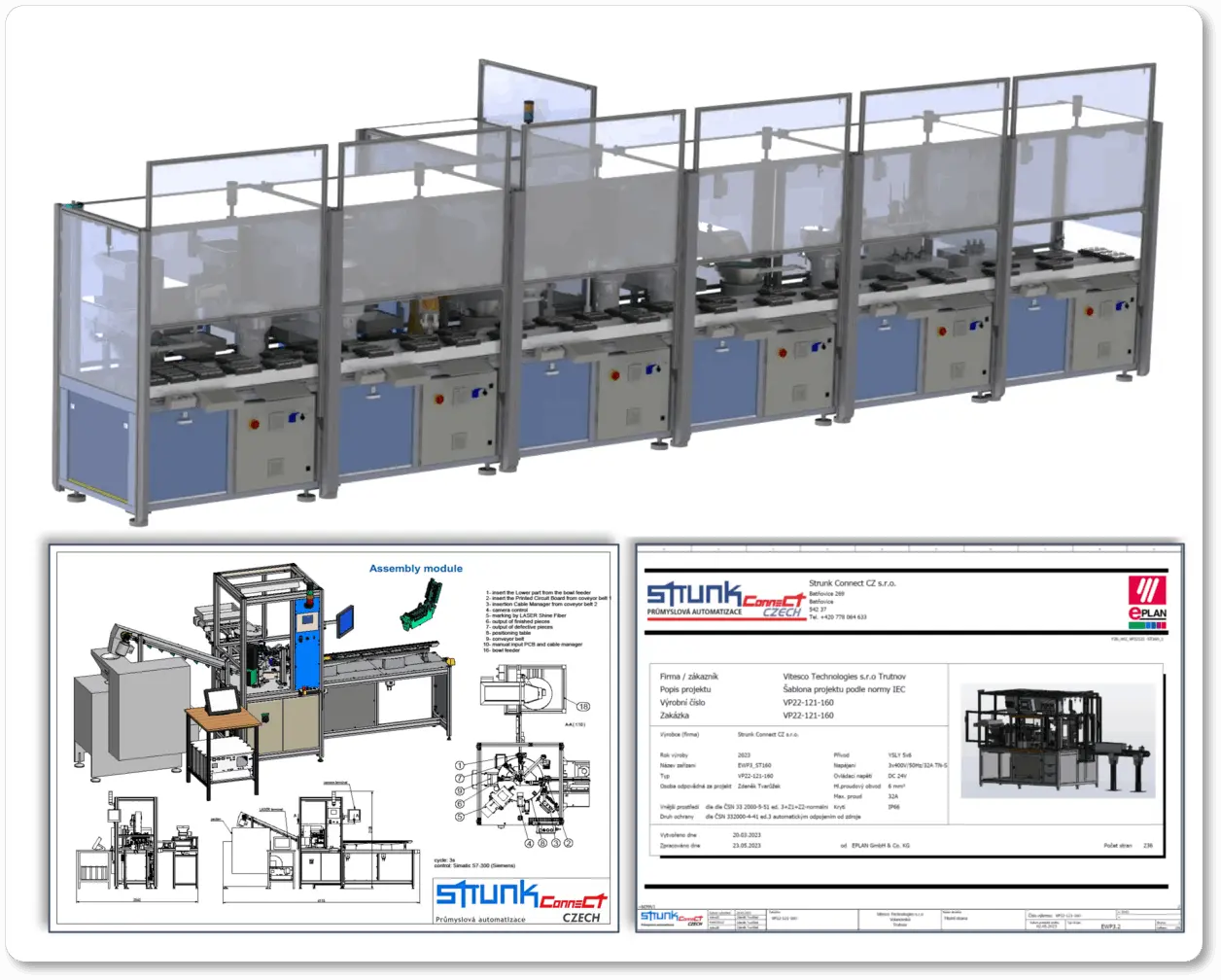

Development and Design of machines and equipment

Our experienced engineers and technicians are ready to work with you on

the design and development of production and testing equipment that corresponds to the nature of the product, the specification of control characters, parameters, process flows and your specific needs.

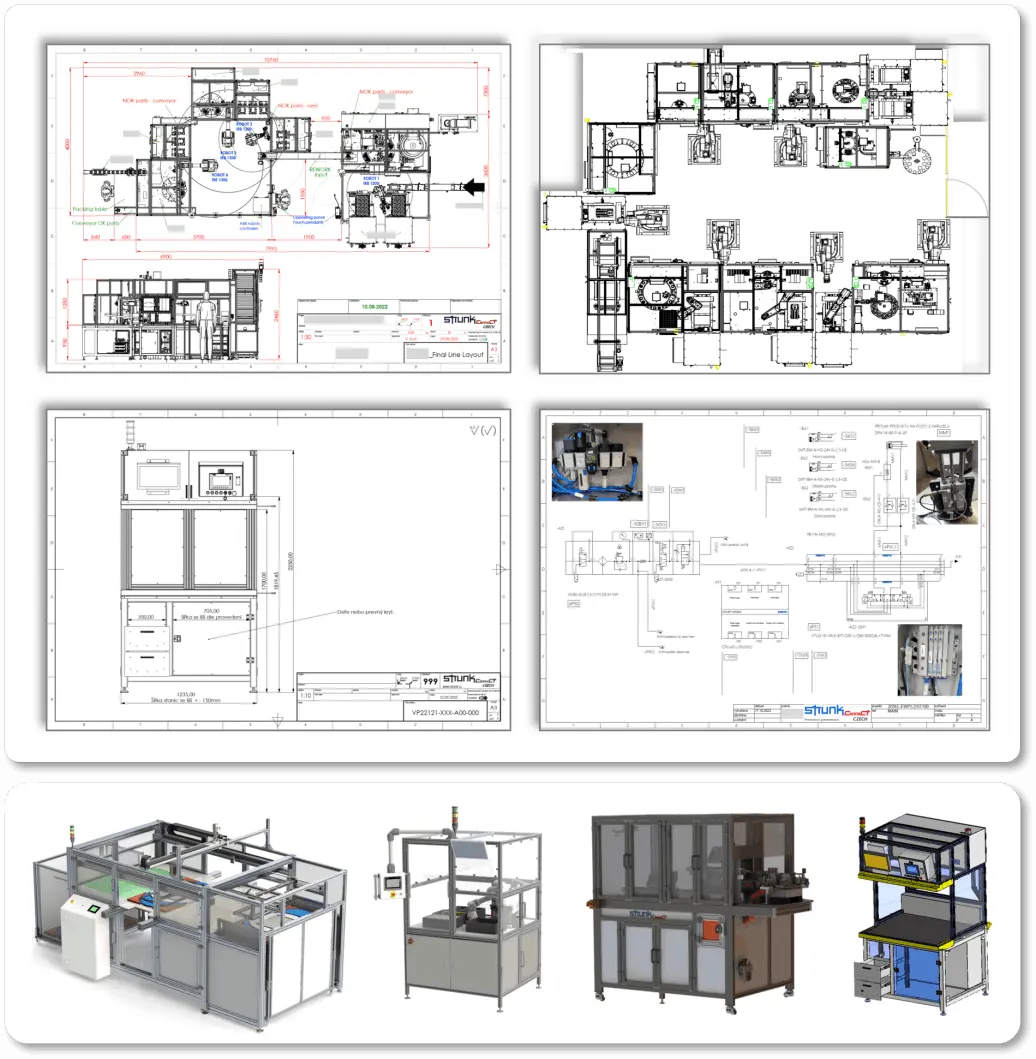

Our services include the complete development and construction of the device from the initial simple design, through the complete CAD design of the device to 3D simulations and virtual commissioning to verify the functions and the required clock rate.

Our designers work in the most modern SW systems for

mechanical and electrical construction.

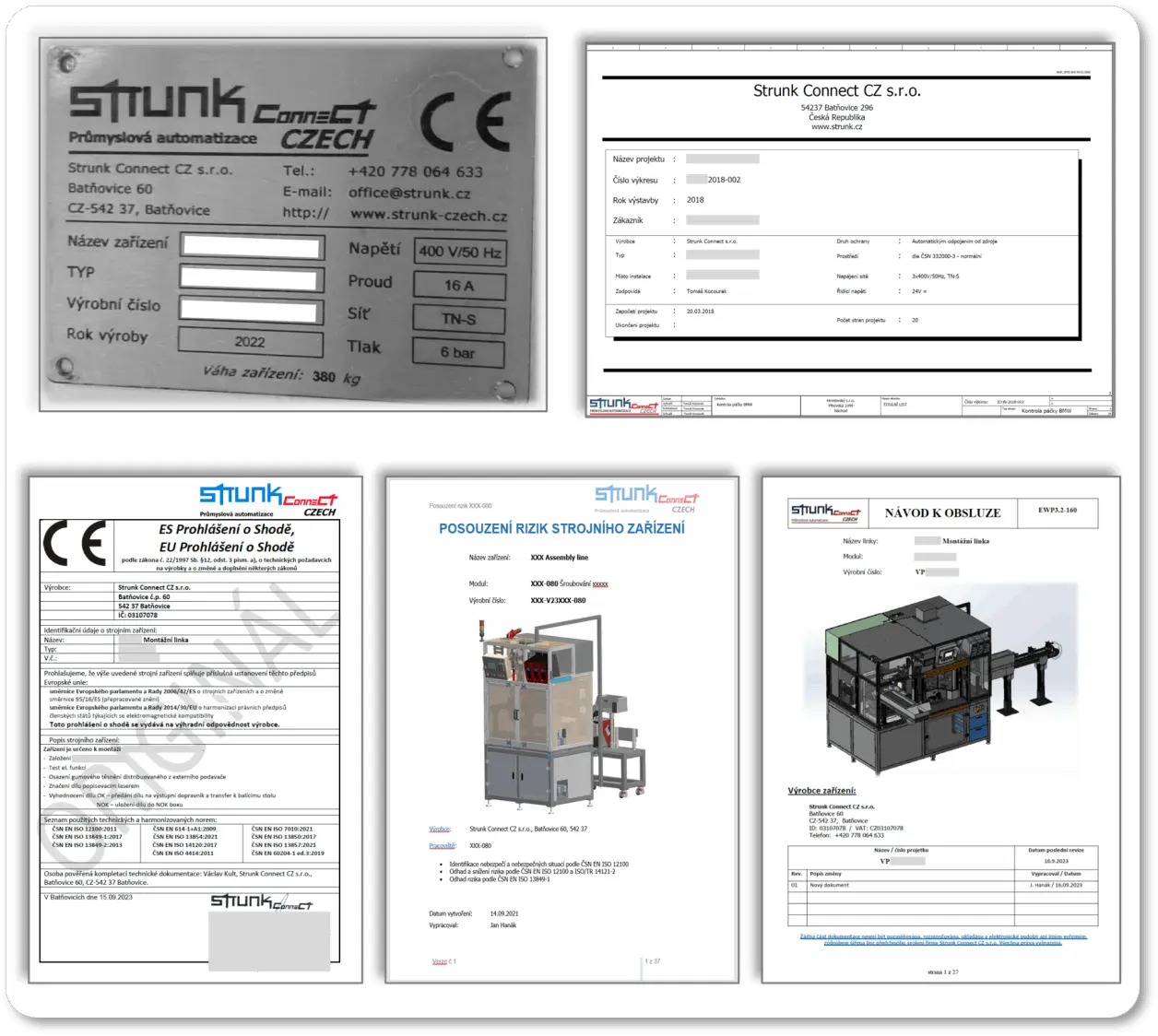

Our machines and equipment are designed and manufactured in strict accordance with the applicable EU machinery safety legislation and standards.

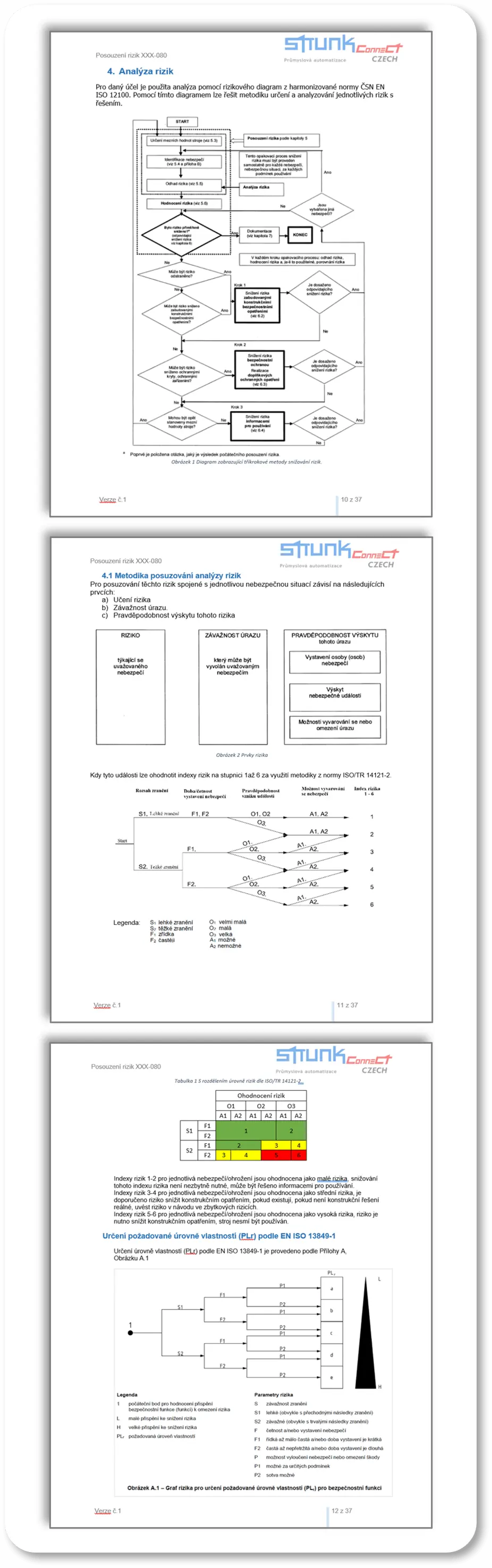

Complete CE documentation is drawn up for each machine, including

a risk assessment with determination of the PLr level, CE declaration of conformity, operating instructions and the final marking of the machine with a production label.