DEVELOPMENT, DESIGN AND MANUFACTURING

single-purpose machines, equipment and lines forindustrial automation

single-purpose machines, equipment and lines forindustrial automation

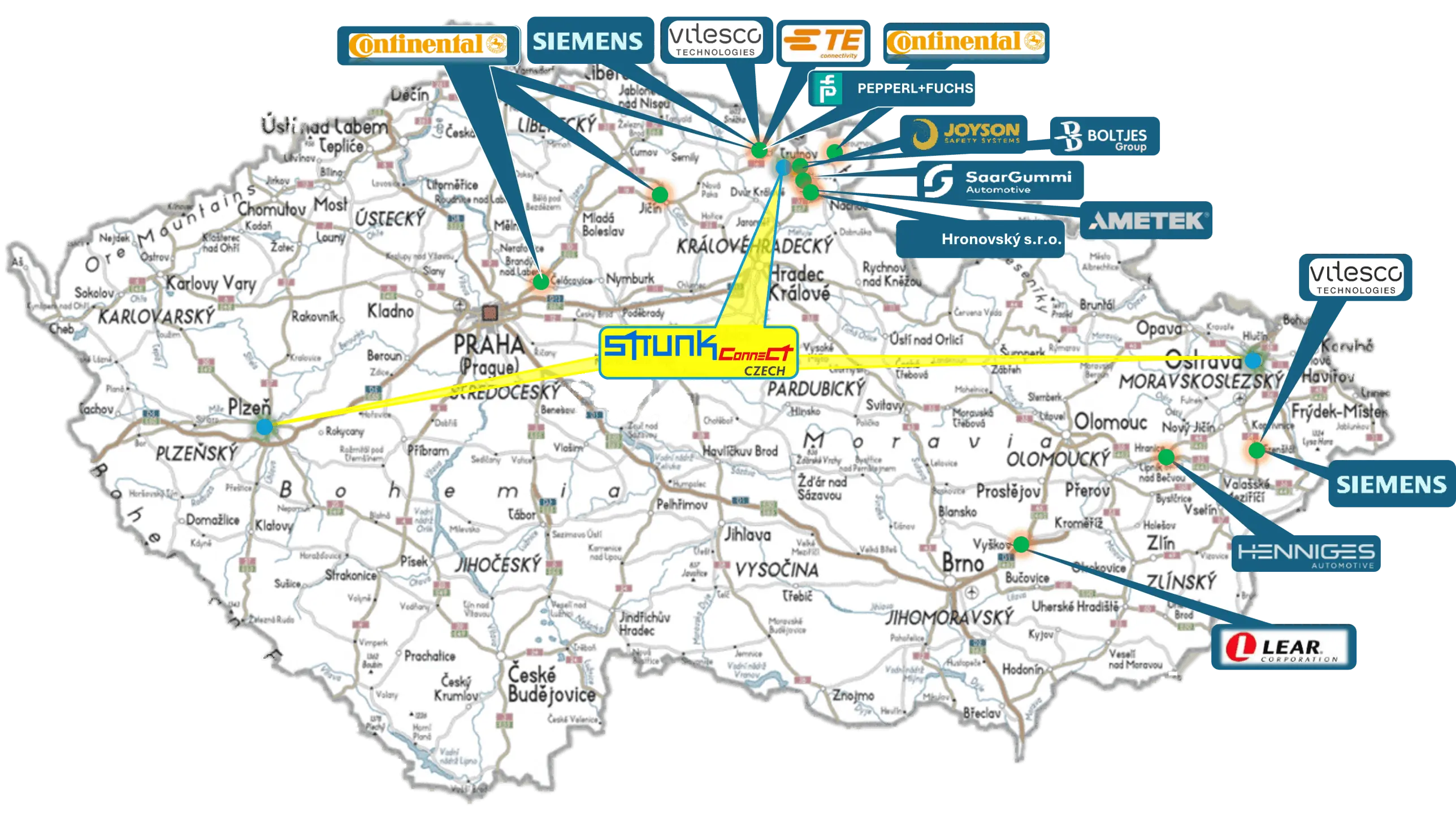

Since 2014, we have been a reliable partner and helper for our customers in solving optimization of their production processes. We ensure the development and production of supporting technologies, from simple fixtures to fully automated production and testing units and assembly lines for full automation of production, testing and packaging, including the integration of service and production robotics.

In case of need and interest of the customer, as part of the cooperation, we also offer serial production of sub-assemblies and final parts based on manual, semi-automatic and fully automatic assembly, testing, sorting and packaging of products, including ensuring regular collection transport.

Streamlining and speeding up the course of production processes, eliminating the influence of the human factor on the production process

Single-purpose machines and equipment, assembly and test lines, robotics

Mechanical 3D construction of machines and equipment

Electro-construction of machines and equipment

Simulation of processes and robotics

Risk assessment & CE documentation

Cabinet design and projection

Testing, validation and revision

Documentation, production label

Assembly and installation

Development and production of our own products and equipment based on the needs of our customers and the market

Ensuring the entire transfer process, starting with the disconnection and professional disassembly of the equipment, packaging, loading, trucking to reassembly and putting the line into operation

Our own CNC machining center primarily intended for the purpose of building machines and equipment

Professional 3D printing studio for the purposes of development and production of parts for industrial use

Custom machines and equipment for various industries

Robotics, PLC control and camera systems that simply work

We will ensure production or repair without unnecessary delays

Guaranteed quality and mechanical safety of the equipment supplied by us